Natural gas has been fueling appliances installed in homes across America since the early 20th century. The piping most commonly used to supply the gas to these appliances is rigid black iron pipe. One of the downsides to using rigid black iron pipe it right in the name, “Rigid.” Rigid black iron pipe isn’t meant to be bent, therefore, installing black iron pipe in a home requires many fittings to make turns and special tools to cut and thread various lengths of pipe. Skilled plumbers install this pipe everyday with incredible precision, but there’s a new kid on the block that is changing up the gas distribution game. Enter CSST.

History of CSST

CSST stands for Corrugated Stainless Steel Tubing. CSST is a flexible gas line that can be used to distribute LP and natural gas. It was developed in Japan the 1980s. The Japanese had trouble with rigid black pipe breaking during earthquakes, so they came up with a flexible alternative that could withstand the movement without breaking. CSST was first sold in America in 1990 and has been gaining popularity ever since. CSST’s flexibility and ease of installation are the reasons more and more contractors are making the switch. Rather than going through the pain of measuring, cutting, threading, cleaning, and fitting black iron pipe, contractors simply pull the CSST from the gas meter to its destination (just like an electrician with wire), cut to desired length and attach a fitting to each end. It’s no wonder why contractors love CSST!

Identifying CSST

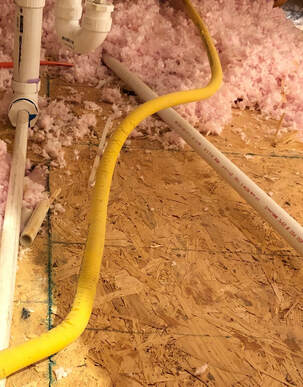

CSST looks very similar to a gas appliance connector. They are often confused for one another. One feature that makes CSST easily distinguishable from a gas connector is its flexible outer jacket. This polyethylene jacket or “sleeve” is usually yellow, but some brands use a black jacket. Gas connectors are also yellow, but this is just a protective coating on the tubing itself. You’ll also notice in the photo below the ridges you can see on the gas connector vs the smoothe jacket on the CSST. There will also be labeling on the outer jacket of the CSST. A popular brand of CSST I often see installed is WARDFlex® from Ward Manufacturing.

Installation Requirements For CSST

Each manufacturer has their own specific installation instructions. Most of them ,however, are very similar. There is one requirement in particular I want to point out. Per the WARDFlex® installation manual:

“Direct bonding is required for all natural and LP gas piping systems incorporating WARDFlex® CSST whether or not the piping system is connected to an electrically powered gas appliance.”

This requirement is generally agreed upon to be one of the most important things to check for when dealing with CSST as it pertains to safety. There have been numerous articles written about the need for CSST bonding. I will discuss this issue in an upcoming post.