Lights generate a lot of heat when they are in use. This heat can be a safety hazard in certain situations where recessed lighting is used. Understanding the difference between IC rated and non-IC rated recessed lighting will help you identify possible fire hazards in your home.

Recessed lighting is a great way to light up your home if you don’t want light fixtures protruding from the ceiling, but there are special considerations you should take into account. There are 2 types of recessed can lights: IC rated and non-IC rated. The IC stands for Insulation Contact, which means just what it sounds like. IC rated fixtures are designed to be installed in areas where they will be in direct contact with insulation. This is important as non-IC rated recessed lighting in contact with insulation creates a fire hazard. The difference between the 2 types of fixtures can be seen in their construction.

IC Rated Fixture Construction

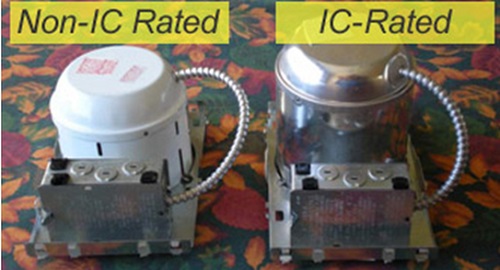

IC rated fixtures are constructed with a double can design or a “can within a can” if you will. The air gap between the 2 cans creates an insulating effect that keeps the outer can cooler. This cooler outer can allows the fixture to be installed in direct contact with insulation without the risk of combustion. IC rated lights provide the proper housing for use with blown in insulation commonly seen in attics today.

Non-IC Rated Fixture Construction

Non IC rated fixtures are built with only a single can or housing and holes in the housing for ventilation. These lights are great for areas where insulation isn’t necessary. The open air surrounding the fixture allows for heat dissipation into the space. These fixtures were traditionally preferred because of their compatibility with higher wattage/brighter light bulbs. They are easily distinguishable from their IC rated counterparts. Non IC rated fixtures usually have a white housing and light can be seen shining through vent holes in the housing, whereas IC rated fixtures have a silver outer housing and no gaps for light to shine through.

Notice the white housing and vent holes on the non-IC rated light

Clearance requirements for Non IC Rated fixtures

Non IC rated light fixtures can be installed in areas where insulation is present. There is a stipulation however. There should be 3 inches of clearance between the fixture and any insulation. This is counter-intuitive though, as that 3 inch gap in the insulation would defeat the purpose of insulation by creating large amounts of uninsulated space. One way to remedy this is to build a box style cover to go over the fixture on the attic side. This box can be made of foil-faced foam insulation or drywall. Once the cover is installed, it can be covered in insulation for peak efficiency. The US Dept of Energy has a great write up on how to properly construct these enclosures that can be found HERE.

How to Identify Non-IC Rated Lights In Your Home

Wondering if the you have the proper recessed lighting installed in your home? Let me show you what to look for so you can perform your own recessed lighting inspection.

While inspecting homes, I find non IC rated can lights buried under insulation from time to time. They are fairly easy to spot as the insulation around them will be glowing. The insulation glows due to the light shining through the ventilation holes in the housing. If you don’t have access to the attic space where the lights are located, such as in vaulted ceilings, you can take the light bulb out and look inside the fixture. The inside of the housing on non-IC rated lights will usually be white just like the outside as opposed to silver on the IC rated lights.

Notice the light shining through the vent holes? Notice the glowing Insulation?

Notice the white housing on the non-IC rated light?